Adds Value to Your Business

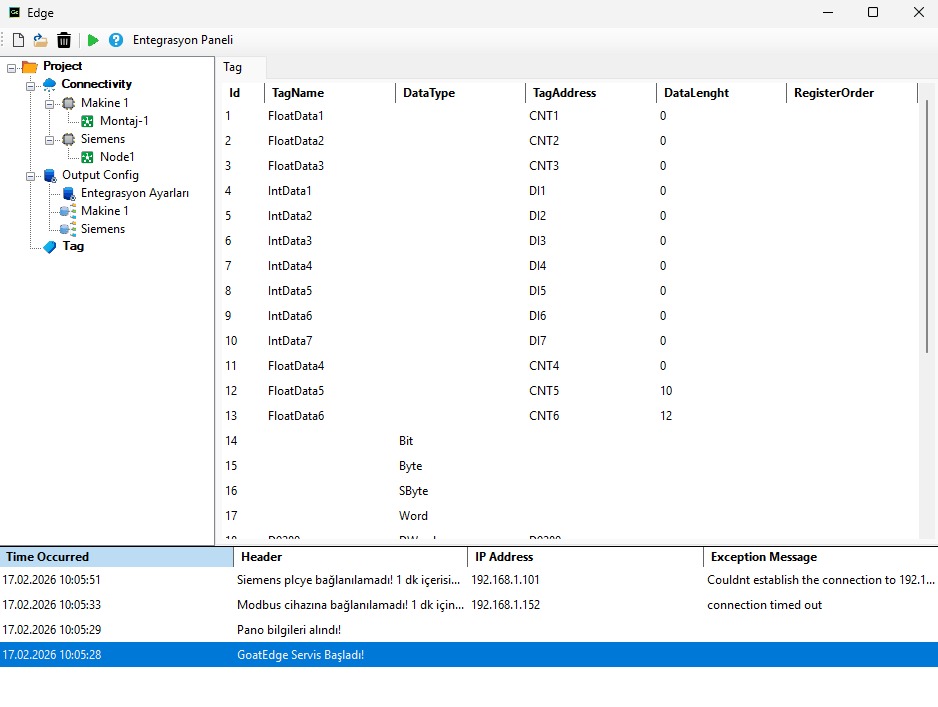

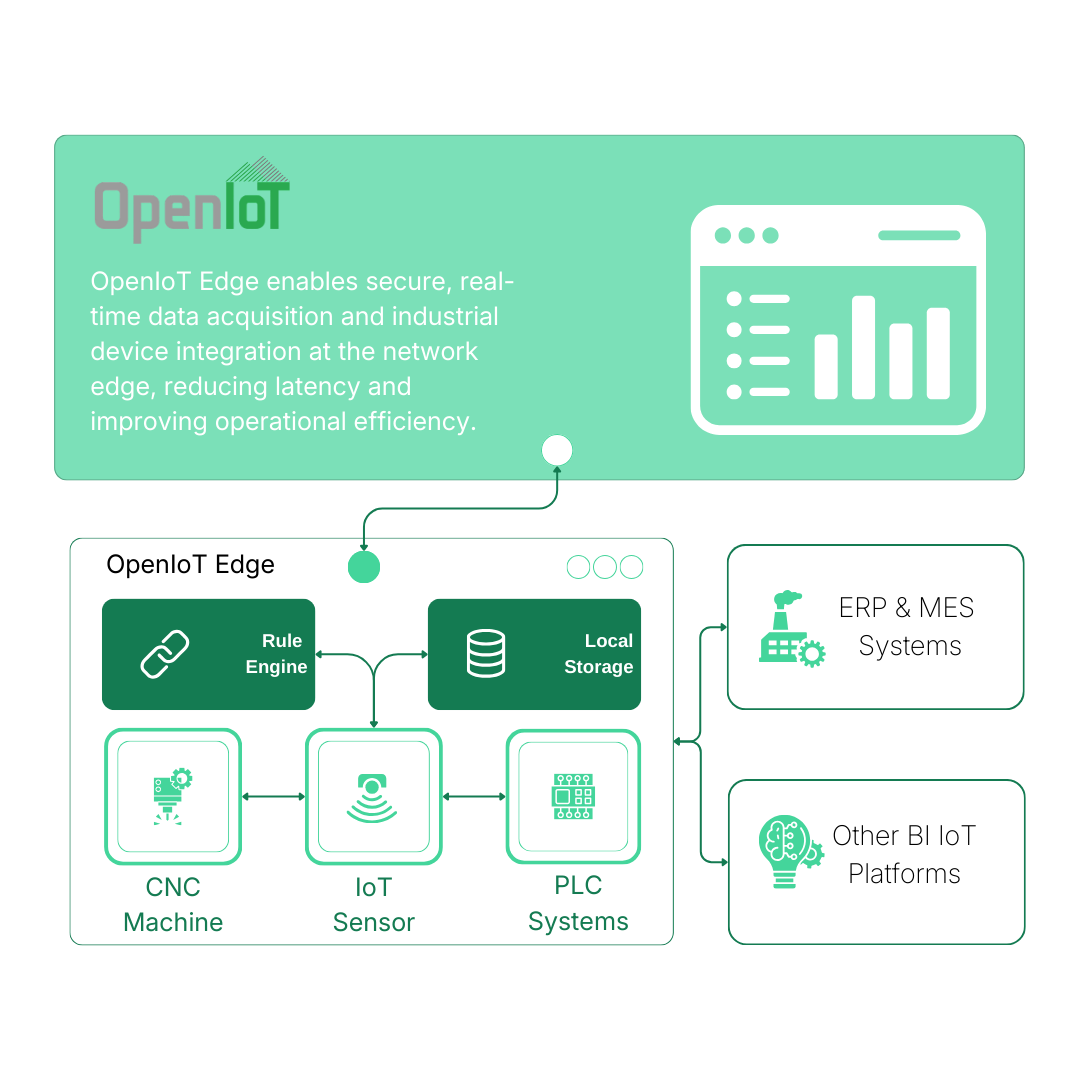

OpenIoT Edge is the connectivity platform that leverages OPC and IT-centric communication protocols to provide a single source of industrial automation data for all your applications.

The platform design allows you to connect, manage, monitor, and control various automation devices and software applications through a single intuitive user interface.