OpenIoT Smart Factory Solution provides real-time visibility, performance optimization, and data-driven decision-making by combining data from machines, PLC systems, and production lines into a single digital platform. It doesn't just monitor your operations; it makes production more efficient, more predictable, and more sustainable.

Contact UsDigitize your production processes from end to end with real-time monitoring, OEE, downtime analysis, scrap and loss analysis, energy tracking, and smart alarm management. OpenIoT integrates with CNC machines, handheld terminals, PLCs, and industrial control systems via advanced connectivity options (MQTT, OPC-UA, Modbus, REST, etc.) to collect all field data in a centralized and scalable architecture.

This reduces downtime, makes production bottlenecks visible, and transforms your factory into a data-driven, high-performance structure.

As part of thermal process management, it offers PID-based control, CCP (Critical Control Point) tracking, temperature validation, data logging, and retrospective traceability infrastructure for heat treatment and temperature-critical production lines. Process safety and quality continuity are guaranteed with HACCP-compliant alarm scenarios and threshold violation notifications.

Our team is a reliable partner for scalable solutions delivered on a fast and steady timeline.

The smart factory solution provides end-to-end visibility for production managers, operations teams, and technical units, enabling efficient, integrated, and scalable production management.

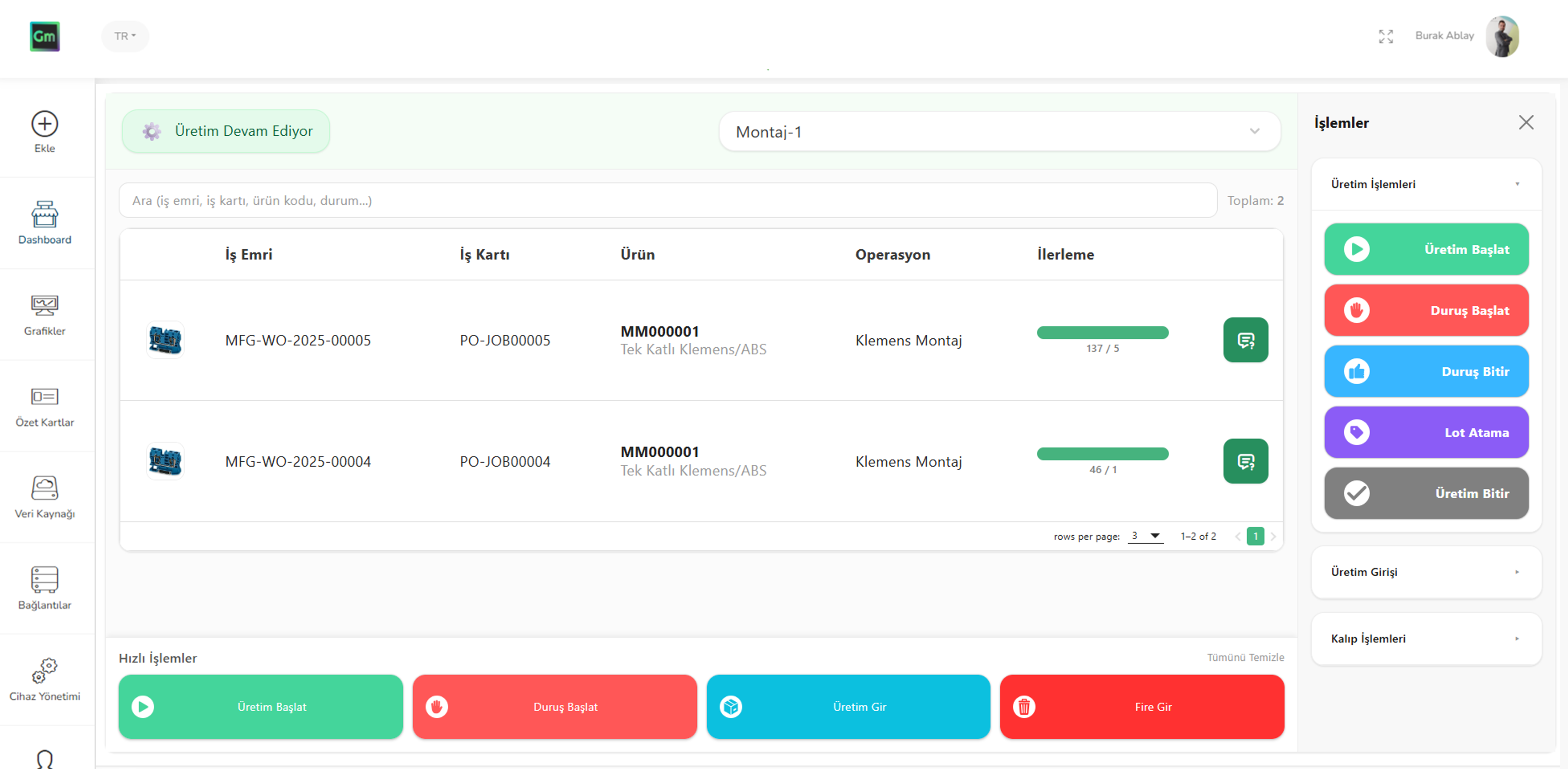

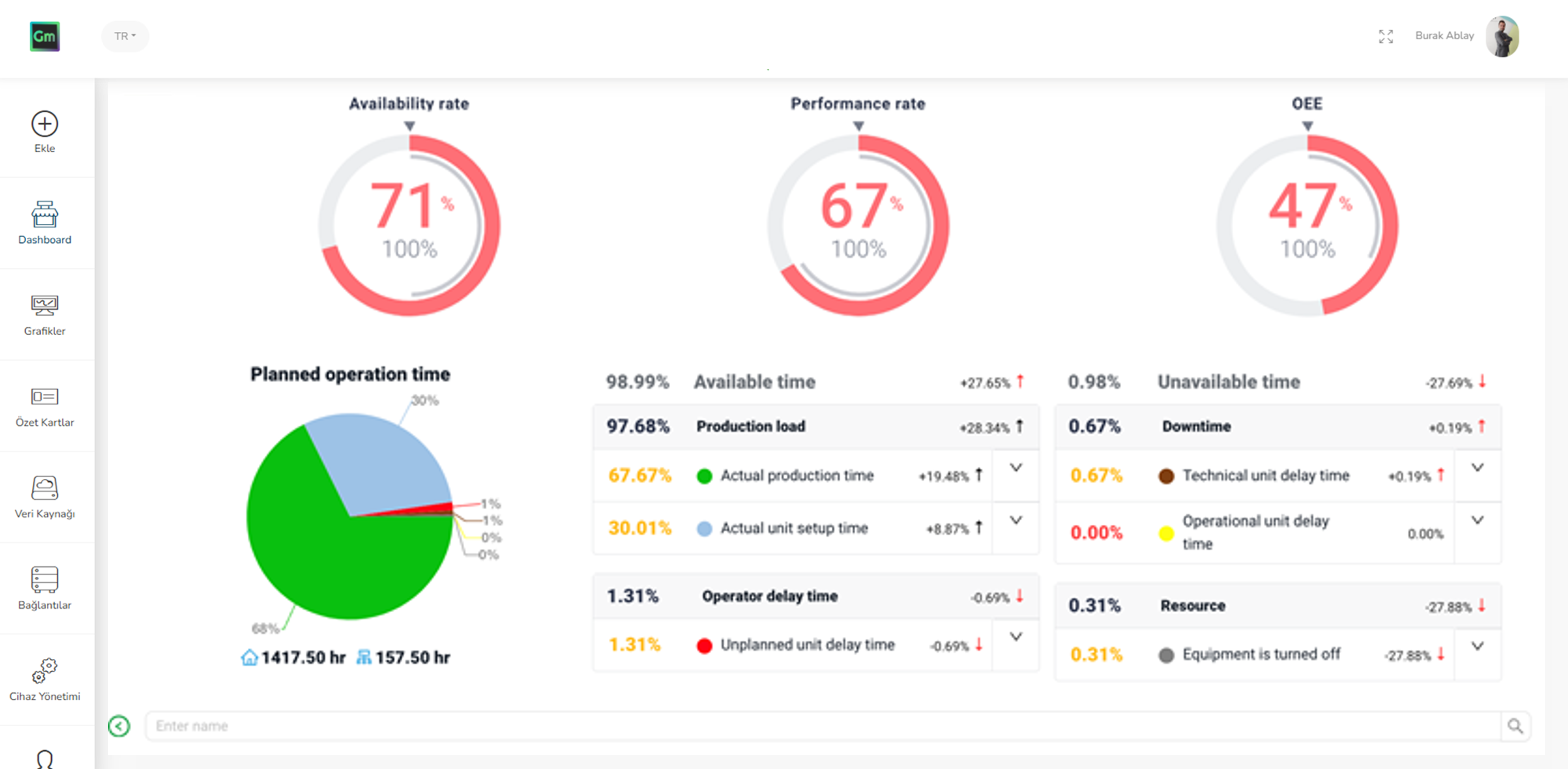

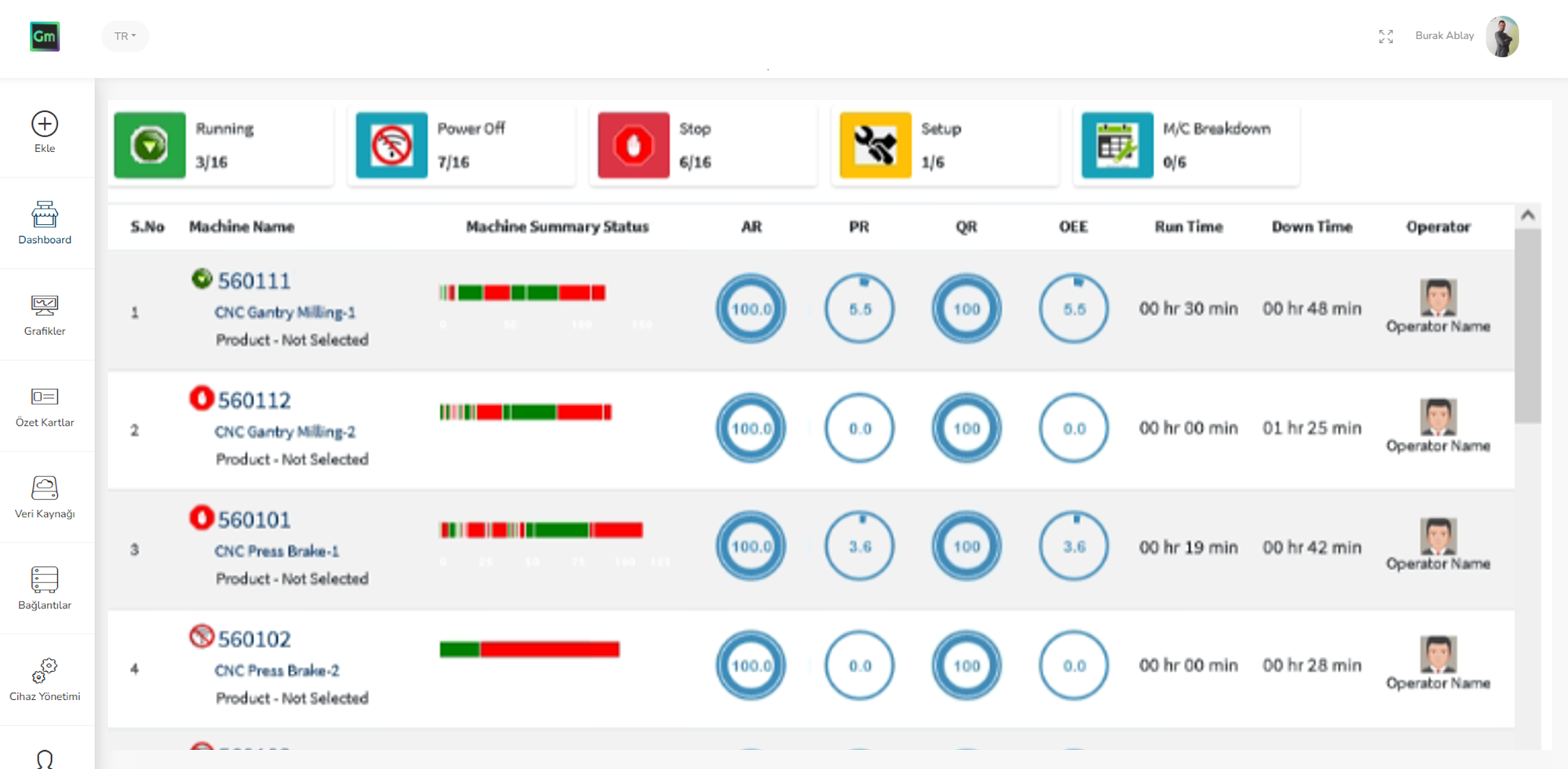

Monitor your production lines, machines, and operational processes in real-time. Make performance, downtime, and capacity data visible on a single screen to enable immediate intervention.

Automatically calculate Overall Equipment Effectiveness (OEE) and critical performance metrics. Identify bottlenecks with data-driven analysis and increase production efficiency.

Continuously analyze machine data to detect failure risks in advance. Reduce unplanned downtime, optimize maintenance costs, and extend equipment life.

Monitor electricity, water, gas, and other resource consumption. Identify energy-intensive points to reduce costs and reach sustainable production goals.

Manage field data directly by integrating with PLC, SCADA, and other industrial systems. Combine production and automation layers into a single digital platform.

Manage all your facilities from a single platform. Easily scale your operations and ensure standardization across different locations thanks to the modular architecture.

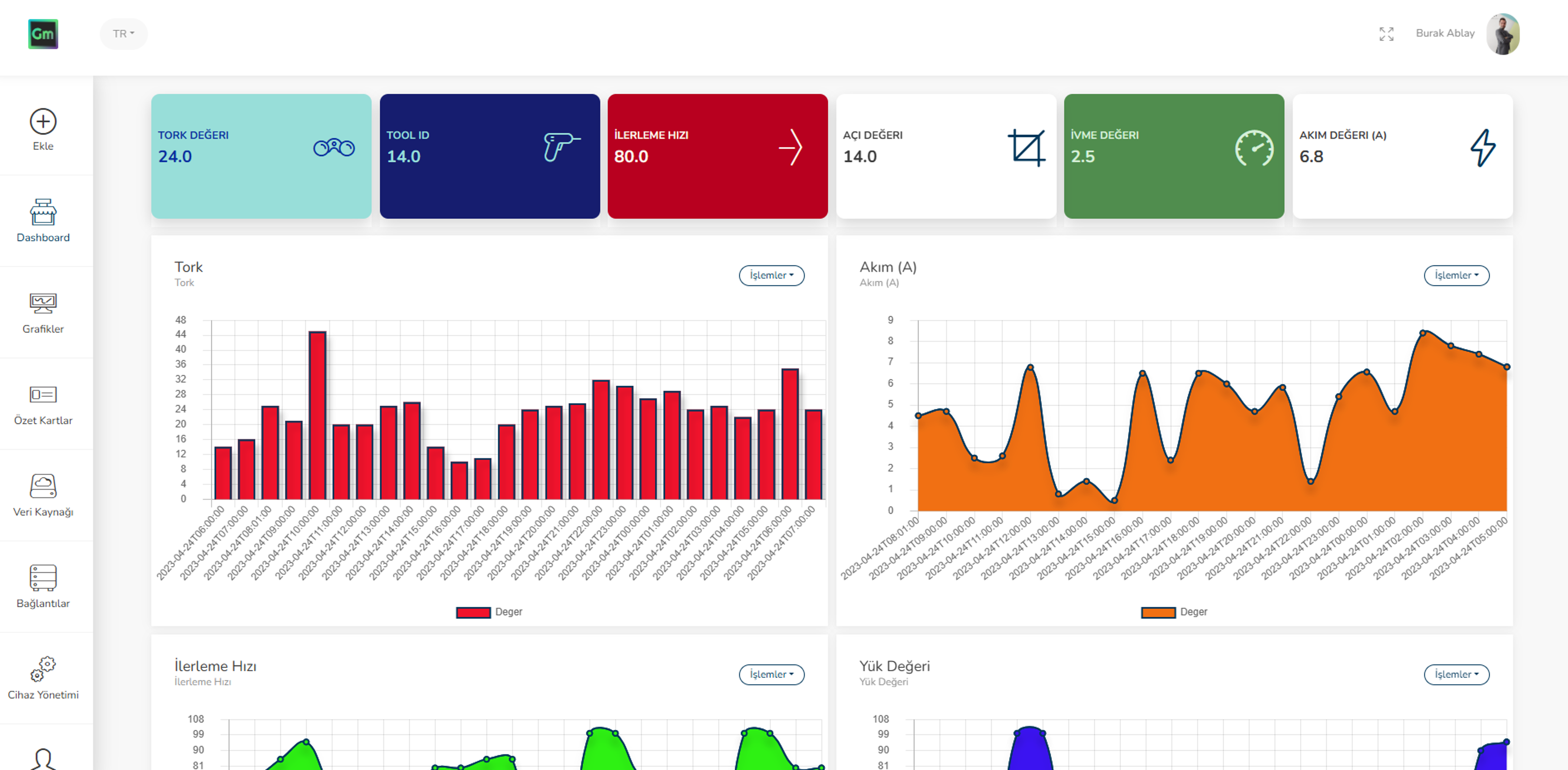

OpenIoT connects directly to CNC machines to collect tool status, spindle data, and alarm codes in real-time. Thanks to this integration provided without the need for an external adapter, machines are integrated quickly and securely into the central OpenIoT platform.

OpenIoT Smart Factory Solution; with its IoT-based monitoring and management infrastructure covering production, quality, energy, and maintenance processes, it can be easily adapted and scaled to production facilities in different sectors. Here are some of the application areas:

OpenIoT provides CCP monitoring by tracking critical process parameters on production lines in real-time. It digitalizes quality processes with HACCP-compliant alarm management and batch-based traceability, reducing downtime and waste.

Cycle time, mold temperature, pressure, and energy consumption data obtained from injection machines are analyzed on the central platform. Production efficiency is increased with OEE calculation, unplanned downtime detection, and mold performance analysis. Data-driven production management is provided.

Spindle status, processing time, alarm codes, and production counts obtained from CNC machines are monitored instantaneously. Bottlenecks are made visible by analyzing operator performance, downtime causes, and capacity utilization. Machine-based efficiency and quality control processes are gathered on a single platform.

All production steps from cell stringing to lamination and test stages are monitored digitally. Production is assured with thermal process monitoring, quality parameter analysis, and serial number-based retrospective traceability. Process optimization is provided with scrap analysis and performance comparisons.

Temperature, draw speed, and tension data coming from extrusion, cooling, and winding lines are continuously analyzed. Deviations are detected immediately by monitoring diameter tolerance and quality parameters. Line efficiency is maximized with energy consumption, downtime analysis, and production plan integration.