SCADA (Supervisory Control and Data Acquisition) systems play a critical role in monitoring and managing industrial processes. From production lines to infrastructure systems, they provide real-time visibility into equipment status and operational data. With the OpenIoT platform, businesses can easily integrate advanced SCADA solutions to increase operational efficiency, optimize costs, and strengthen system reliability.

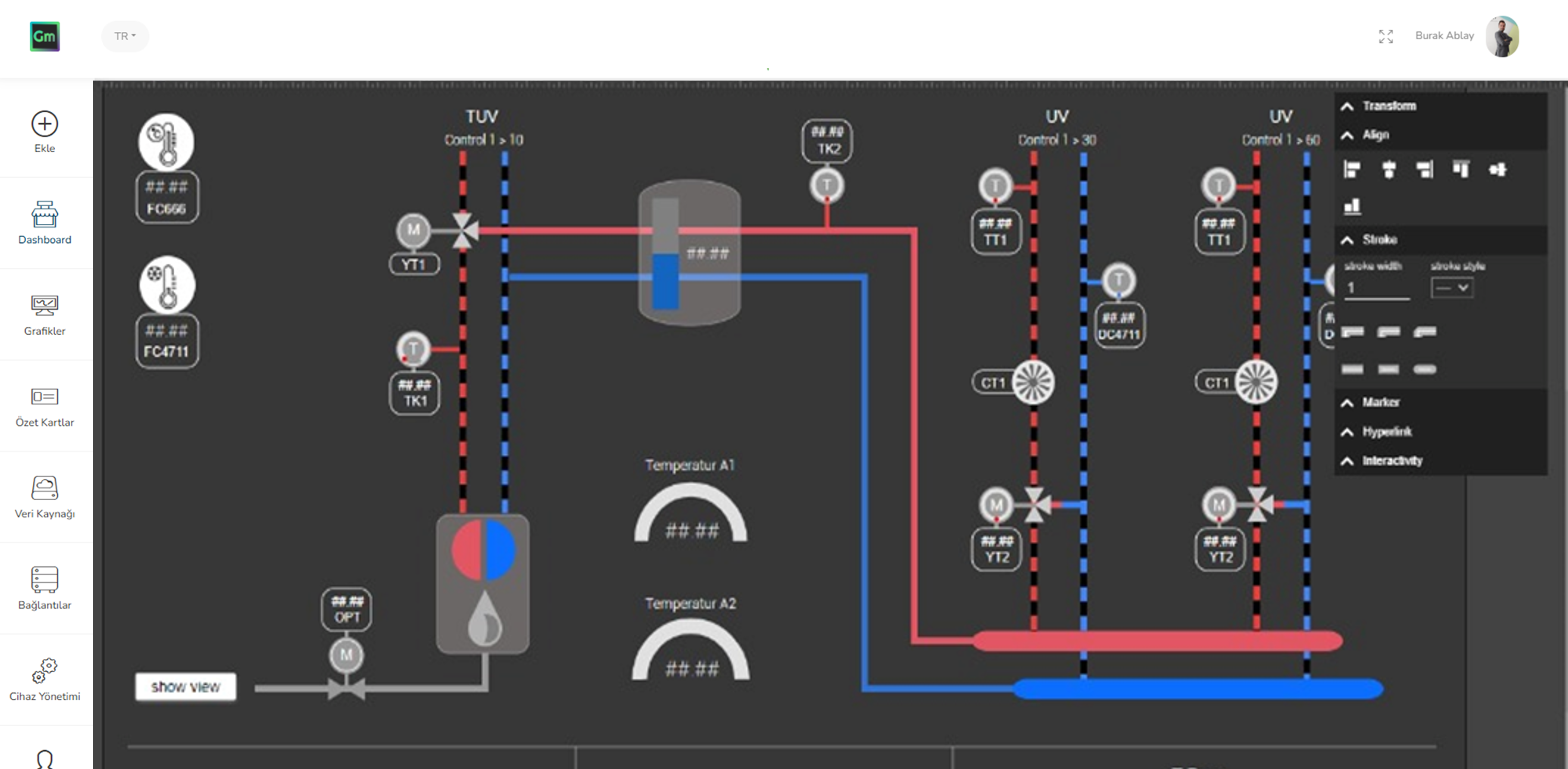

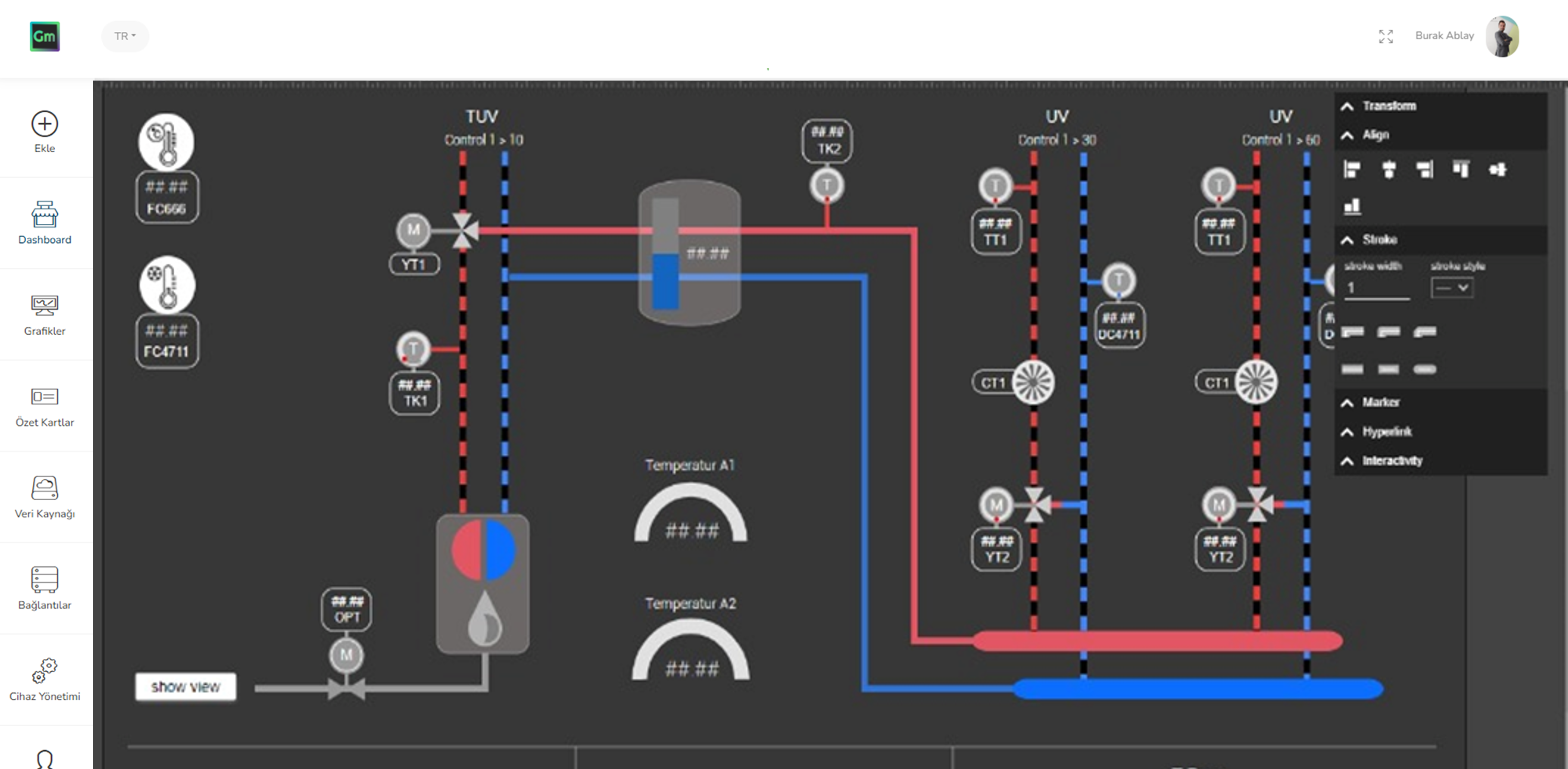

The ability to collect, analyze, and visualize data from multiple sources allows operators to make more informed decisions and respond quickly to changing operational conditions. The OpenIoT platform provides comprehensive tools for data collection, processing, and visualization from SCADA components such as PLCs, RTUs, control systems, and field devices, creating seamless integration opportunities with various industrial processes.

With OpenIoT, you can monitor equipment performance in real-time, detect inefficiencies, analyze operational trends, and intervene immediately in abnormalities. This approach ensures more efficient, safe, and sustainable management of systems in a wide range of use cases, from manufacturing to infrastructure management.

Our team is a reliable partner for scalable solutions delivered on a fast and consistent timeline.

The OpenIoT SCADA solution provides end-to-end visibility for manufacturing facilities, operators, and technical teams, offering efficient, automated, and scalable industrial management.

The OpenIoT platform seamlessly integrates your SCADA infrastructure with PLCs, RTUs, and industrial control devices. It offers reliable data collection, monitoring, and control through Modbus, OPC UA, BACnet, and other industrial communication protocols.

It forms the integration layer between classic automation systems and modern IoT platforms. Thanks to features like local data collection, protocol conversion, and secure data transmission, it ensures uninterrupted transfer of field data to the system.

By transforming collected data into meaningful insights, you can perform real-time analysis. Thanks to the rule engine and automation scenarios, it optimizes operational processes and accelerates decision-making mechanisms.

It reduces operational risks with an advanced alarm management system. Definable alarm rules, threshold values, and automatic action mechanisms ensure instant intervention in critical situations and events.

It offers a flexible notification infrastructure for critical events. Real-time alerts can be sent via email, SMS, and mobile notifications. In this way, teams are informed about the system status at any time and can take quick action.

Thanks to customizable visuals, dynamic components, and real-time data flow, you can monitor all your operational data on a single screen, increase performance, and manage processes centrally.

The OpenIoT SCADA system enables real-time monitoring and management of energy production facilities and renewable energy sources. Production performance, equipment status, and operational data are analyzed on a centralized platform to increase efficiency and reduce the risk of downtime.

The OpenIoT SCADA solution is highly adaptable and meets critical needs in various industrial sectors. It offers a wide range of applications with real-time monitoring, rule-based automation, and scalable architecture:

Monitoring of machine data, optimization of production processes, and increasing operational efficiency.

Centralized management of transportation, environmental monitoring, infrastructure management, and city operations.

Monitoring of energy production, distribution, and consumption data, management of equipment performance.

Centralized management of HVAC, security, access control, and building automation systems.

Monitoring of infrastructure equipment, alarm management, and ensuring operational continuity.