Modern businesses managing liquid storage, from fuel to water, have a critical need for continuous tank level monitoring and infrastructure status control. Inadequate monitoring can lead to leaks, equipment failures, and higher operating costs. In this context, IoT-powered solutions become indispensable for digital transformation. OpenIoT IoT platform overcomes these challenges with ease.

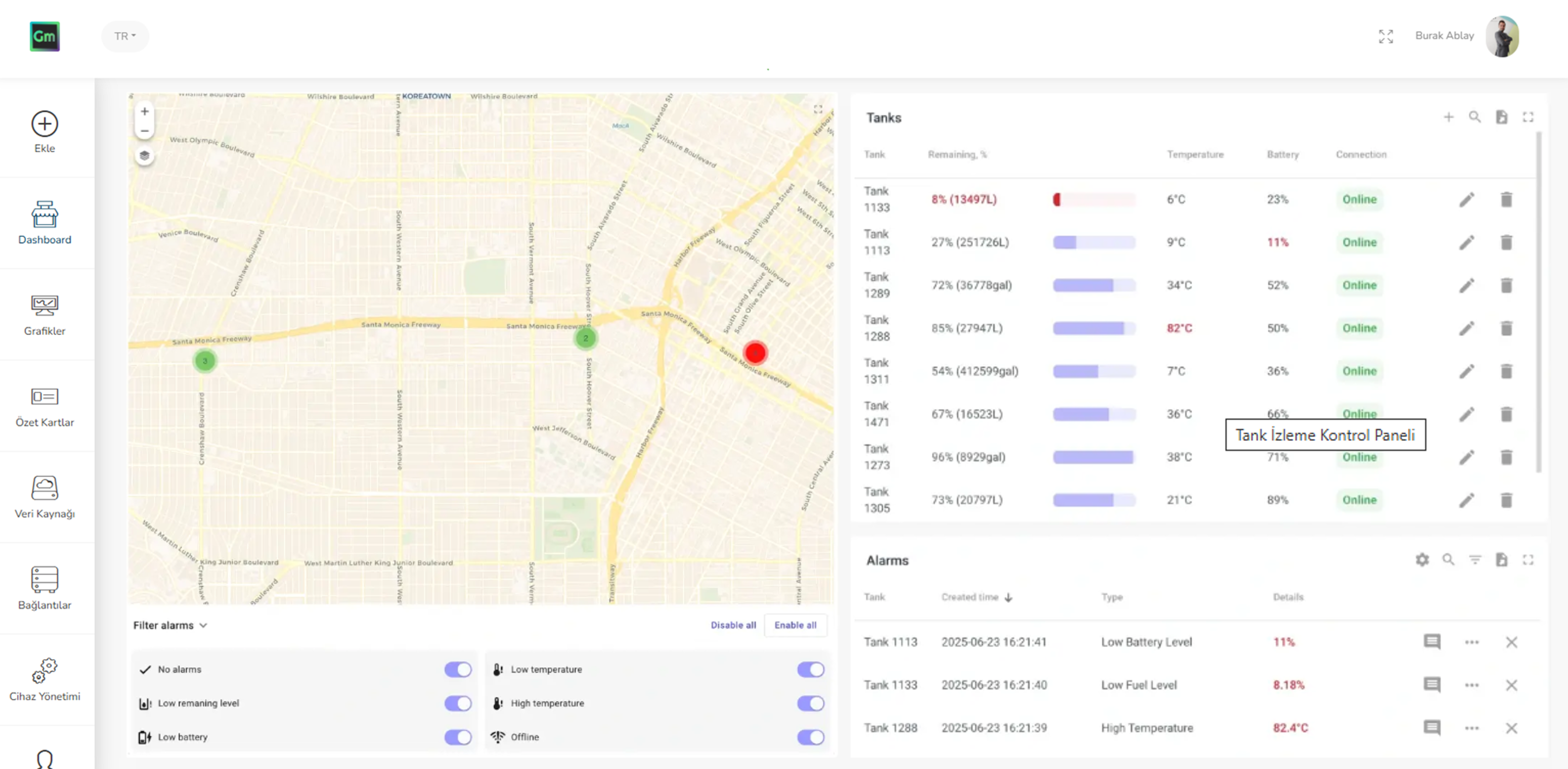

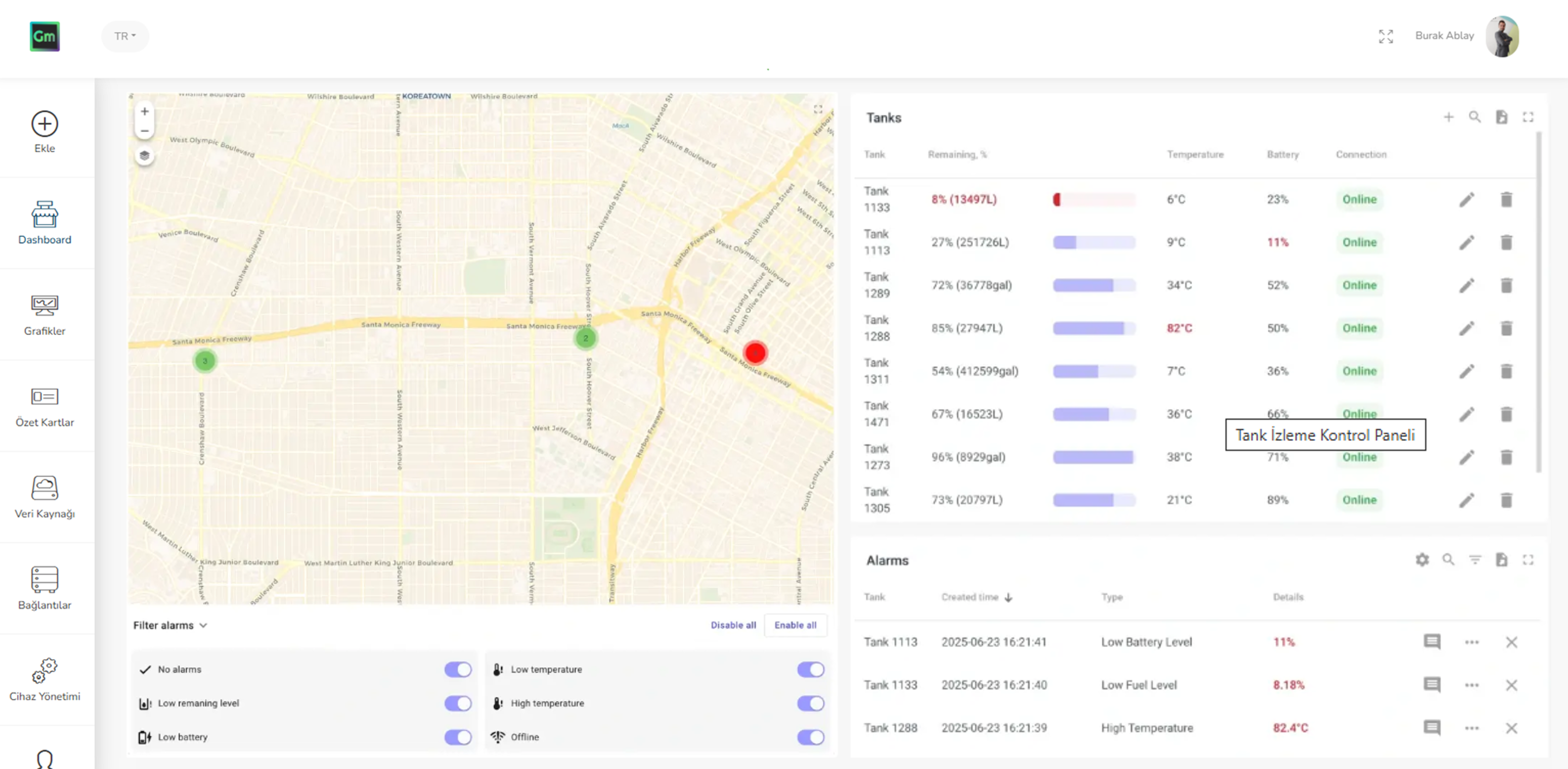

Contact UsThe OpenIoT platform offers a comprehensive tank level monitoring approach that provides real-time tracking of key metrics such as volume, temperature, sensor battery level, and connectivity status. Thanks to its flexibility, OpenIoT can be easily adapted to meet industry-specific needs, whether for small-scale or enterprise-wide deployments.

OpenIoT stands out with its scalability, multi-protocol support (MQTT, HTTP, CoAP, and others), customizable dashboards, and robust device management tools. It enables users to deploy both local and cloud-based solutions that effectively monitor distributed tank networks at any scale.

Our team is a reliable partner for scalable solutions delivered on a fast and consistent timeline.

The OpenIoT-based tank level monitoring solution automates liquid storage monitoring at any scale and complexity. With its strong support for industrial protocols, real-time visualization, rule-based alarm system, and device control, it is a perfect solution for B2B businesses, public infrastructure, and industrial environments. Enhanced transparency and timely alerts increase operational efficiency and reduce costs.

Tank level monitoring systems ensure safe and efficient management by monitoring the fill levels and operational status of liquid, chemical, fuel, or raw material storage tanks in real-time. With the OpenIoT platform, the entire tank infrastructure can be centrally tracked, analyzed, and optimized with automated control mechanisms.

Tank occupancy rates are monitored instantly to detect critical levels early. The risks of overflow, depletion, or operational interruption are reduced.

By analyzing occupancy data, filling and shipping processes are optimized. Stock management improves and unnecessary operation costs are prevented.

Tanks in different locations can be monitored and managed via a single platform. Users can check the system status with remote access.

Dangerous situations are detected early by monitoring critical parameters such as pressure, temperature, and level. Security is increased with alarm mechanisms.

Maintenance needs are pre-determined by analyzing sensor and equipment data. Unplanned failures decrease and system continuity is ensured.

Collected data is reported in detail and consumption trends and operation performance are analyzed. With data-based decisions, costs are reduced and efficiency increases.

OpenIoT's Tank Level Monitoring Solution can be adapted to a wide variety of industries and meets their specific needs:

Enables remote monitoring of fuel tanks, automated alarm system, and minimum maintenance requirements.

Tracks water or fertilizer tank levels on farms with location-based analysis and consumption forecasting.

Manages city tanks for drinking water or chemical storage with centralized monitoring and regulatory reporting.

Integrated with GPS and routing systems, it tracks fuel levels in fleet tankers and depots.

Audits chemical storage tanks in industrial environments for compliance and safety.